Atlantic Poly Blog

Branding with Bags

Consider using custom plastic bags to promote your business. Using a branded bag to promote your business is effective when your business requires customers to use a bag to transport their purchases in. Having your company's logo on the bag, along with its name and tag line goes a long way in increasing the brand recall of your business.

Dry cleaners, grocery stores and deli’s are perfect examples of businesses that can use branded plastic bags from Atlantic Poly. Atlantic Poly’s Clear Dry Cleaning bags are made with hanger holes, sloped shoulders and are available in roll form for easy dispensing. Dry Cleaning Garment Bags on Rolls are perfect for protecting everything in your wardrobe from dust and dirt, and keeping them wrinkle free! We also supply both reusable and recyclable plastic grocery and shopping bags to many grocery store chains and retail stores across the US.

For branded plastic bags or printed poly bags with your logo or company information, we have the capabilities to imprint poly bags in up to eight colors on two sides. Keep in mind, the print needs to be bold and legible, and the message

should be easy to read from a distance. Generally, it is best to print

in a bold color with a font that is easy on the eyes. Printed Poly Bags, or branded plastic bags, are useful for many different industries. And, we can print as few as 5,000 bags. We also have complete layout and graphic services available for your convenience. For getting your name out there on bags, Call Atlantic Poly today.

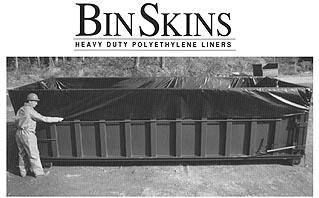

Roll Off Dumpster Liners Decrease the Potential for Airborne Contamination

Many people will wonder, what is a Roll Off Dumpster Liner? A dumpster liner, in many ways, can be considered to be a massive garbage bag. However, many more attributes are used to specify dumpster liners, such as thicknesses, colors, sizes, chemical make-ups, uses, manufacturing techniques, and packaging. Even more importantly, there are many different liner requirements/types based on your company's specific application. Concrete companies, asbestos abatement companies, environmental service corporations, and others rely on Roll Off Dumpster Liners to contain materials which may be hazardous to public health or our environment. The liner is easily installed and the dumpster is ready to use in no time. in the US (varies by state), environmental laws require the use of dumpster liners. This is necessary so when a dumpster is being transported there is contaminated liquid dripping.

Many manufacturing facilities produce a daily amount of liquid refuse or semi-solid refuse. These companies use dumpster liners, or BinSkins for daily operation. BinSkins are mainly black opaque in color and thicknesses typically range from 3 MIL thick to 12 MIL thick. The most popular container sizes are 20, 30 and 40 yard. However, at Atlantic Poly we also make drum liners and liners are also made for larger applications such as railway trailers and truck trailers and you may request a quote for any of these larger sizes. BinSkins are easily installed by one person and are designed to have an overhang on each side, so that the liner may be secured by tying it off to hooks, and taping or tying in knots to avoid having it blow off. Contact Atlantic Poly for your BinSkins order.

Polyethylene Plastic and Disaster Preparation--Is Your Business Prepared?

Our hearts pour out to victims of natural disasters worldwide. Today, we focus on the immense suffering of the citizens of Japan. Sadly, the recent events in Japan serve as a stark reminder of the importance of business “disaster preparedness”. Obviously, for the Japanese business owners who took the wave head-on, no amount of disaster prep would have made a difference. However, just beyond the wave perimeter, unprepared business owners are “sunk” because they now lack the ability to protect investments from the elements.

Closer to home, this winter's massive snow crushed protective shelters all across America and exposed business plant, property, equipment, and inventory to the elements. Those owners who manage a proactive disaster preparation program maintain custom-made Poly Shrouds and Bags to blanket irreplaceable business machinery that don’t respond well to water.

We never get away from the threat of high winds, tornadoes, hurricanes, fire, and water. Somewhere today, a business owner in America will be victimized by the unexpected and will soon realize the immense value of his ready stock of Atlantic Poly Polyethylene Roll Stock sitting ready in the warehouse.

No business can afford to allow disaster prep to be an afterthought. Atlantic Poly stands ready to both prepare you for the unexpected and to help you sleep better at night for so doing.

Our Polyethylene Bags Have Many Purposes and Are Reusable

Plastic bags aren’t just used for household purposes they can serve industrial purposes as well. Self-adhesive, resalable drawstring or tote bags are the most commonly used plastic bag. Shrink bags, and durable plastic bags for heavy machinery are all used daily in the industrial areas. Many food items that are available these days come in a wide variety of plastic bags, each suiting a different purpose. Some bags that are used in the vegetable and fruit sections come in rolls that can be easily cut off. These have opening at one end and do not have any sealing attachments.

Plastic bags aren’t just used for household purposes they can serve industrial purposes as well. Self-adhesive, resalable drawstring or tote bags are the most commonly used plastic bag. Shrink bags, and durable plastic bags for heavy machinery are all used daily in the industrial areas. Many food items that are available these days come in a wide variety of plastic bags, each suiting a different purpose. Some bags that are used in the vegetable and fruit sections come in rolls that can be easily cut off. These have opening at one end and do not have any sealing attachments. Plastic bags that need to be vacuum-free are made of more durable plastic and are closed from all sides except for a small opening through which the air is sucked out to create a vacuum inside before sealing it. Many of the bags Atlantic Poly provides are supplied to grocery chains, and when consumers use those bags they become useful bags for other items they own. Contact us today to learn more about our poly products and how you can get your supply of poly goods.

Atlantic Poly Uses Biodegradable Plastics with Their EnviroTech Recycling Division

This new technology produces plastic which degrades by a process of OXO-degradation. The technology is based on a very small amount of pro-degradant additive being introduced into the manufacturing process, thereby changing the behavior of the plastic. Degradation begins when the programmed service life is over and the product is no longer required. There is little or no additional cost involved in products made with this technology, which can be made with the same machinery and workforce as conventional plastic products.

The length of time it takes for oxo-biodegradable products to degrade can be ‘programmed’ at the time of manufacture and can be as little as a few months or as much as a few years. They are protected from degradation by special antioxidants until ready for use, and storage-life will be extended if the products are kept in cool, dark conditions.

The length of time it takes for oxo-biodegradable products to degrade can be ‘programmed’ at the time of manufacture and can be as little as a few months or as much as a few years. They are protected from degradation by special antioxidants until ready for use, and storage-life will be extended if the products are kept in cool, dark conditions.

Unlike PVC, the polymers from which oxo-biodegradable plastics are made do not contain organo-chlorine. Nor do oxo-biodegradable polymers contain PCBs, nor do they emit methane or nitrous oxide even under anaerobic conditions. Only oxo-biodegradable can be economically recycled. Its counter part, hydro-biodegradable is more expensive. Contact us today to learn more about recycling plastics and be sure to check out our eco-friendly plastic products.

Atlantic Poly Offers a Wide Selection of Consumer Product Packaging Options

We have people tell us that it is hard to get a complete understanding of what Atlantic Poly does. This is a common problem (a good problem by the way) for any firm that offers a myriad of custom product offerings. Therefore, for simplicity sake, when you think “Atlantic Poly”, think “product packaging”. It is no more complicated than that.

If you manufacture goods, we package your goods for shipment. If your property or plant requires protection from the environmental element, we seal, wrap and protect. We manufacture everything from plastic grocery/shopping bags to “Polyethylene roll off bin liners” and most everything in-between.

There is an application for Atlantic Poly products in every single consumer market. However, a number of specialized markets prove to be our biggest draws. They are:

We offer sixteen total unique product categories with multiple custom product offerings within each category. For example, our "Polyethylene Bags" product category spans thirteen different product offerings that range from Dry Cleaning Bags to Discount Shrink Film. Lean about each in detail by visiting our website’s product pages.

How Stretch Film Can Help Transport Your Materials

Stretch film and shrink wrap are a commonly used packaging materials used in industries to secure items to a pallet or crate. Industrial film and shrink wrap provide important protection of goods and binds them to a pallet or crate for safe transportation or storage by keeping the items tightly bound and protected from the elements. Most film and shrink wrap is composed of polyethylene and PVC. By wrapping many layers of these materials to an object to be placed on a pallet, they offer secure holding.

The film/wrap can be wrapped automatically or semi-automatically using specialized machinery or it can be wrapped manually. The film is pliable, thin and sticks to itself, so there is no hassle in trying to knot, glue or staple it closed. But because they are used in the industry, the sheets of stretch film and shrink wrap used with machinery are much longer and wider, and depending on the size of the goods to be wrapped, the sometimes require specialized machinery to get it around the object and the pallet. They can be ordered according to the manufacturers/suppliers sizes in mm or yards.

The film/wrap can be wrapped automatically or semi-automatically using specialized machinery or it can be wrapped manually. The film is pliable, thin and sticks to itself, so there is no hassle in trying to knot, glue or staple it closed. But because they are used in the industry, the sheets of stretch film and shrink wrap used with machinery are much longer and wider, and depending on the size of the goods to be wrapped, the sometimes require specialized machinery to get it around the object and the pallet. They can be ordered according to the manufacturers/suppliers sizes in mm or yards.

Not only is this material used in the transportation of objects and goods, it is also widely used to protect them in storage facilities such as warehouses. One of the advantages of using stretch film is that it is not a very expensive protective material and can be used on all kinds of materials. It can be used on machinery, chemicals and furniture. We have a wide selection of stretch film for all your business needs, so please feel free to contact us today to learn more about our polyethylene products.

Roll Off Dumpster Liners are Important for Most Commercial Businesses

A dumpster liner is a massive garbage bag. Of course, there is much more to dumpster liners, such as several thicknesses, sizes, chemical make-ups, uses, manufacturing techniques, and packaging. Most importantly, there are many different liner requirements, each based on a company's specific needs. Concrete companies, asbestos abatement professionals, environmental service corporations and many more rely on Roll Off Dumpster Liners daily to contain materials which may be harmful to others or our environment. Liners are often purchased in addition to renting a container. From New Hampshire to Kansas to California, environmental laws demand the use of dumpster liners.

As an owner, manager or site superintendent if you ask yourself "do i need roll off dumpster liners?" the answer is most likely yes. Insulation and asbestos abatement professionals are required by law to contain and encapsulate any materials which have been found to be hazardous to the public's health. Concrete companies have been the target of environmental agencies for years. The main concern with regards to concrete is the run-off or intentional pouring of wash out material. Man made disasters such as the gulf coast oil spill and hurricane Katrina make liners a must. There is no American who wants to see a dumpster driving down the highway dripping contaminated liquid. In other cases, many manufacturing facilities produce a daily amount of liquid refuse or semi-solid refuse. Again, these companies depend on liners for daily operation to maintain man-hours spent on clean up.

As an owner, manager or site superintendent if you ask yourself "do i need roll off dumpster liners?" the answer is most likely yes. Insulation and asbestos abatement professionals are required by law to contain and encapsulate any materials which have been found to be hazardous to the public's health. Concrete companies have been the target of environmental agencies for years. The main concern with regards to concrete is the run-off or intentional pouring of wash out material. Man made disasters such as the gulf coast oil spill and hurricane Katrina make liners a must. There is no American who wants to see a dumpster driving down the highway dripping contaminated liquid. In other cases, many manufacturing facilities produce a daily amount of liquid refuse or semi-solid refuse. Again, these companies depend on liners for daily operation to maintain man-hours spent on clean up.

These liners are manufactured much like a trash-can liner or garbage bag. Low-density polyethylene (LDPE) is what is commonly referred to as a plastic garbage bag. This resin is used to produce a Roll Off Dumpster Liner. LDPE has a recycle number of 4. One positive is that the majority of these liners used to keep our streets clean are made of recycled resins. We have our standard sizes but feel free to contact us or request a quote for any other size and we'll be happy to help.

Protect Your Shipping Materials With Atlantic Poly's Bubble Wrap

A lot of us have had it happen before when you either send or receive an item and the item that is inside it suffers a breakage during delivery. You can often tell in an instant and before you have even opened it that what is inside is broken because you can hear the rattle of the numerous pieces inside. Obviously this is something that you do not want to be happening. The best way to stop this from happening is by making sure that when you send any packages, you ensure that any fragile items are surrounded by adequate cushioning. Bubble wrap is the most effective and used product to protect your goods when shipping.

Since bubble wrap was invented in the late 1950's it has gone on to become a world wide product used on a daily basis. The bubble wrap that we have is available a vary of sizes, with the smallest usually being around 6mm in diameter and the larger ones being more than 25mm diameter. The different sizes are suitable for different needs. Smaller diameter sheets are generally stronger and more resistant to bursting so can provide good protection for more fragile items. On the other hand, the larger diameter sheeting provides a softer cushioning which is perfect for use on larger items that are not as susceptible to breakages.

Since bubble wrap was invented in the late 1950's it has gone on to become a world wide product used on a daily basis. The bubble wrap that we have is available a vary of sizes, with the smallest usually being around 6mm in diameter and the larger ones being more than 25mm diameter. The different sizes are suitable for different needs. Smaller diameter sheets are generally stronger and more resistant to bursting so can provide good protection for more fragile items. On the other hand, the larger diameter sheeting provides a softer cushioning which is perfect for use on larger items that are not as susceptible to breakages.

Whether you are sending items during a move or it is for your commercial business Atlantic Poly has got you covered in helping your product be safe and secure with our bubble wrap. It is extremely advisable to make sure you pack your goods properly and using bubble wrap to protect items is a very good way of doing so. We have been servicing our customers for over 28 years. Every month, we

ship millions of poly bags and other packaging products. So contact us today should you need any polyethylene products or poly packing supplies.

Biodegradable Plastics: The Two Main Types and How They Work

The world-wide demand for plastics continues to skyrocket. The early plastics were non-biodegradable and now rest in landfills for thousands of years to come. Scientists were quick to recognize this environmental threat and matured plastics manufacturing industry into the multi-faceted biodegradable industry that it is today. Today, two main biodegradable plastics prevail the market: oxo-biodegradable and hydro-biodegradable.

The two products have similarities. In both cases degradation begins with a chemical process (oxidation and hydrolysis respectively), followed by a biological process and both types emit CO2 as they degrade. Both types are compostable.

Hydro-biodegradable is much more expensive than oxo-biodegradable to manufacture. Hydro-biodegradable also emits methane during the decomposition process. For these and other more technical reasons, only oxo-biodegradable can be economically recycled.

So, if you are environmentally conscious, look to be a consumer of oxo-biodegradable consumer plastics. Atlantic Poly specializes in producing custom oxo-biodegradable consumer plastics and we will be glad to help you and your company “go green” in a most economical fashion.